무료 샘플과 쿠폰을 받으려면 연락하세요.

왓츠앱:0086 18588475571

웨이 채팅: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

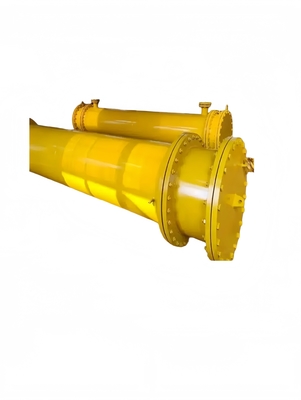

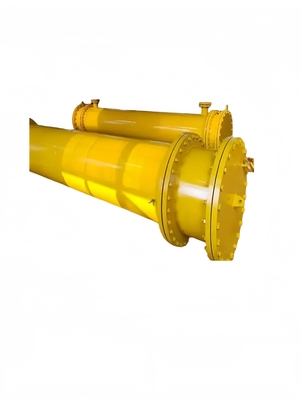

x| 설계 압력 | 0.1-10mpa | 작업 온도 | -196-550 ℃ |

|---|---|---|---|

| 무게 | 280 KG | 내부 재료 | 구리 튜브, 이중 상 강철, PTFE 안감 |

| 외부 재료 | 탄소강, 스테인레스 스틸, 티타늄 합금, 하스텔로이 합금 | 디자인 표준 | ASME |

| 구조 유형 | 분리 가능/고정 튜브 시트/이중 튜브/U 자형 튜브 | 열 교환 영역 | 10m2/50m2/200m2 |

| 핵심 구성 요소 | 압력 용기 | 용량 | 사용자 정의 가능 |

| 치수 | 사용자 정의 가능 | 설계 온도 | -196 ℃ -550 ℃ |

| 사용자 정의 지원 | 비표준 크기/인터페이스 플랜지 사용자 정의 | 압력 용기 | 예 |

| 재료 옵션 | 다수의 | ||

| 강조하다 | 10m2 플로팅 헤드 열교환기,ASME 표준 열교환기,ASME 플로팅 헤드 열교환기 |

||

| 속성 | 가치 |

|---|---|

| 설계 표준 | ASME |

| 디자인 압력 | 0.1~10 MPa |

| 작업 온도 | -196°C ~ 550°C |

| 열 교환 부위 | 10m2/50m2/200m2 (자격화 가능) |

| 무게 | 280kg |

| 보증 | 1년 |

| 핵심 부품 | 압력 용기 |

| 구조 유형 | 분리 가능/ 고정 튜브 엽/ 듀플 튜브/U 모양 튜브 |

- 사용자 정의 가능한 디자인:특정 요구 사항을 충족시키기 위해 다양한 크기, 압력 및 열 교환 영역에서 사용할 수 있습니다

- 정밀 온도 조절:최적의 성능을 위해 안정적인 작동 온도를 유지

- 지속가능 한 건축물:구리 튜브, 듀얼 파즈 스틸, PTFE 인라인 등 고품질 소재로 만들어졌습니다.

- 다재다능한 응용:석유화학, 에너지 및 식품 가공 산업에 적합합니다.

- 유연한 구성:분리 가능, 고정 된 튜브 잎, 이중 튜브 및 U 모양 튜브 디자인으로 제공됩니다.

내부 재료:구리 튜브, 듀얼 파스 스틸, PTFE 부리

외부 재료:탄소강, 스테인리스강, 티타늄 합금, 하스텔로이 합금

모든 단위는 다음을 포함합니다.

- 영상 출입 검사 문서

- 기계 시험 보고

- 1년 보증

우리는 다음과 같은 포괄적인 사용자 정의 옵션을 제공합니다:

- 비표준 크기

- 인터페이스 플랜지 사용자 정의

- 맞춤형 차원 (L × W × H)

- 특정 용량 요구 사항

상하이 Sureway는 생산 기술, 완전한 프로젝트 실행 및 장비 공급에 특화된 주요 화학 엔지니어링 기업입니다.황화학제품과 기체제품에 대한 전문지식, 우리는 최적화된 생산 기술 패키지 및 턴키 솔루션을 제공합니다.

우리의 최첨단 기술은 공기 분리, LNG 시설, 바이오 가스 정화 및 산업 가스 회수 등 응용 분야에 서비스를 제공합니다.우리는 이산화탄소 생산 기술에 대한 여러 국가 특허를 보유하고 있습니다.

Q: 품질을 어떻게 보장합니까?

A: 우리는 출하 전에 사전 생산 샘플과 최종 검사를 수행합니다.

Q: 어떤 서비스를 제공합니까?

A: 우리는 LNG 공장, CO2 공장, 가스 분리 공장 및 다양한 화학 처리 장비에 대한 기술 지원 및 장비를 제공합니다.

Q: 지불 조건은?

A: 우리는 T/T, L/C, 신용카드 등 다양한 지불 방법을 받아 들이며, 여러 배송 조건이 있습니다.